Processing Technology

EV Tech will employ Lepidico’s hydro-metallurgical process, characterized by low energy consumption. This method utilizes cost-effective conventional reagents and industry-standard equipment.

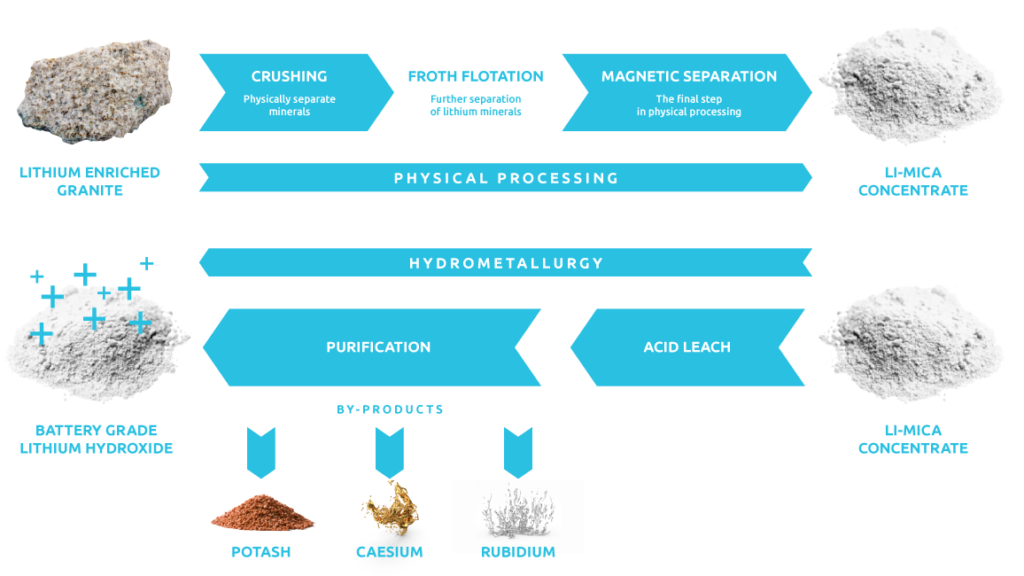

The processing plant’s comminution section will include: loading from the feed bunker, crushing using a vibrating grizzly and a jaw crusher, clay removal through a washing trommel, secondary crushing via a cone crusher, rod milling with multiple stages of classification and desliming. The deslimed and milled material will undergo flotation and possibly magnetic separation to yield a lithium mica-rich concentrate.

This effort has shaped the process flow sheet designated for the construction of the demonstration plant at the TreLith Processing Site. The plant is intended to generate commercial samples of lithium hydroxide for assessment by end-users, including battery producers and automotive Original Equipment Manufacturers. Additionally, the Demonstration Plant will yield samples of by-products like gypsum, sulphate of potash, caesium, and rubidium sulphate alum. While the Company has conducted thorough metallurgical testing of these processes at a pilot scale, the construction of a demonstration-scale plant aims to validate the scalability and commercial viability of the technology.